What We Do

Plastic Injection Molds

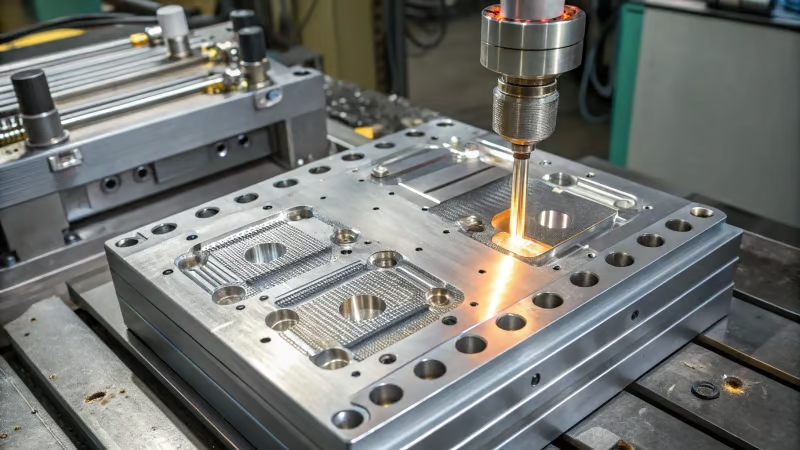

After designing a custom plastic part, the next step is creating the plastic injection mold. Mingyu uses advanced software, skilled designers, and CNC machinery to build high-quality molds for plastic injection, ensuring excellent molded parts.

The mold is the largest upfront investment and a key factor in part quality. When choosing an injection molding supplier in China, it’s crucial to find one with in-house mold manufacturing capabilities for better project control and quality assurance.

Our experts are ready to help with your mold build and custom molded parts.

In-House Mold Builds

All of Mingyu’s customer molds are built in our Dongguan facility, where experienced designers and machinists use modern software and CNC machinery. Once part designs are approved, we create robust, trouble-free plastic injection molds for your production needs.

For new tooling, having single source responsibility ensures better quality, fewer delays, and no unforeseen costs. If your supplier doesn't build molds in-house, it could lead to significant issues.

Let us assist you in sourcing high-quality parts and tooling for your injection molding project.

Lifetime Warranty

Whatever type of plastic injection mold you need, we understand that your injection mold purchase will become a significant asset to your business. For that reason, we warranty the production life of molds we build for our customers for the life of their production requirements.

We will help you better understand plastic injection mold construction and their cost. The quality of your custom plastic parts will first depend on the quality of your mold. Let us quote your next injection molding project and we will work closely with you to make your project a success!

Molds for Plastic Injection

High-quality plastic parts start with a quality built injection mold. The mold for your custom parts can be a big investment, so we’ll work with you every step of the way to ensure you’re familiar with the different types of molds for plastic injection that are available, and we’ll make sure you’re completely informed before you invest. Below we provide you with a valuable understanding of basic injection mold construction types and the benefits of each.

Insert Molds

Insert molds have a cavity side and core side insert that fit inside of a custom mold base here at Mingyu. They are a great way for us to offer customers economical tooling at very rapid lead times. The insert style design is great for small and medium size parts that require low quantity part orders or fast delivery of parts. Even though insert molds are low cost in basic design, they are made with the same high quality materials and components as free standing plastic injection molds and provide the same high quality defect free parts.

Free Standing Molds

Free standing molds, also known as stand-alone molds, provide an all-in-one design. They are built to include the mold base, inserts, and all components needed to be fully functional alone. A properly designed free-standing mold is built for production inside any SPI standard injection molding machine that is sized properly for the mold. Stand-alone molds have a higher cost, but they are a good choice for multi-cavity production and with high-quantity orders.

Why Do Plastic Injection Molds Cost So Much?

People often ask why plastic injection molds cost so much? Here is the answer – Producing high quality plastic parts can only be achieved by using a high quality built mold. Molds for plastic injection consist of precisely machined components made from various metals such as aircraft grade aluminum or hardened mold steels. These molds are designed and made by highly skilled and well paid people categorically called “mold makers”. They have spent years and possibly even decades being trained in the mold making trade. Additionally, mold makers need very expensive tools to perform their job, such as very expensive software, CNC machinery, tooling, and precision fixtures. The amount of time that mold makers need to finish a plastic injection mold can range from a few days to several weeks depending on the complexity and size of the end product.

Advantages of Molds Made in China

Having your custom molded plastic parts made in China can offer consistent quality and lower overall costs. Ming yu plastic injection molding factory use high-tech equipment and offer reliable technical expertise. In addition, if you source your project to a reputable China injection molding supplier they will consistently use high-quality materials unlike many offshore suppliers. Interaction with our molding experts throughout the process ensures the timely production of the best possible molded plastic parts.

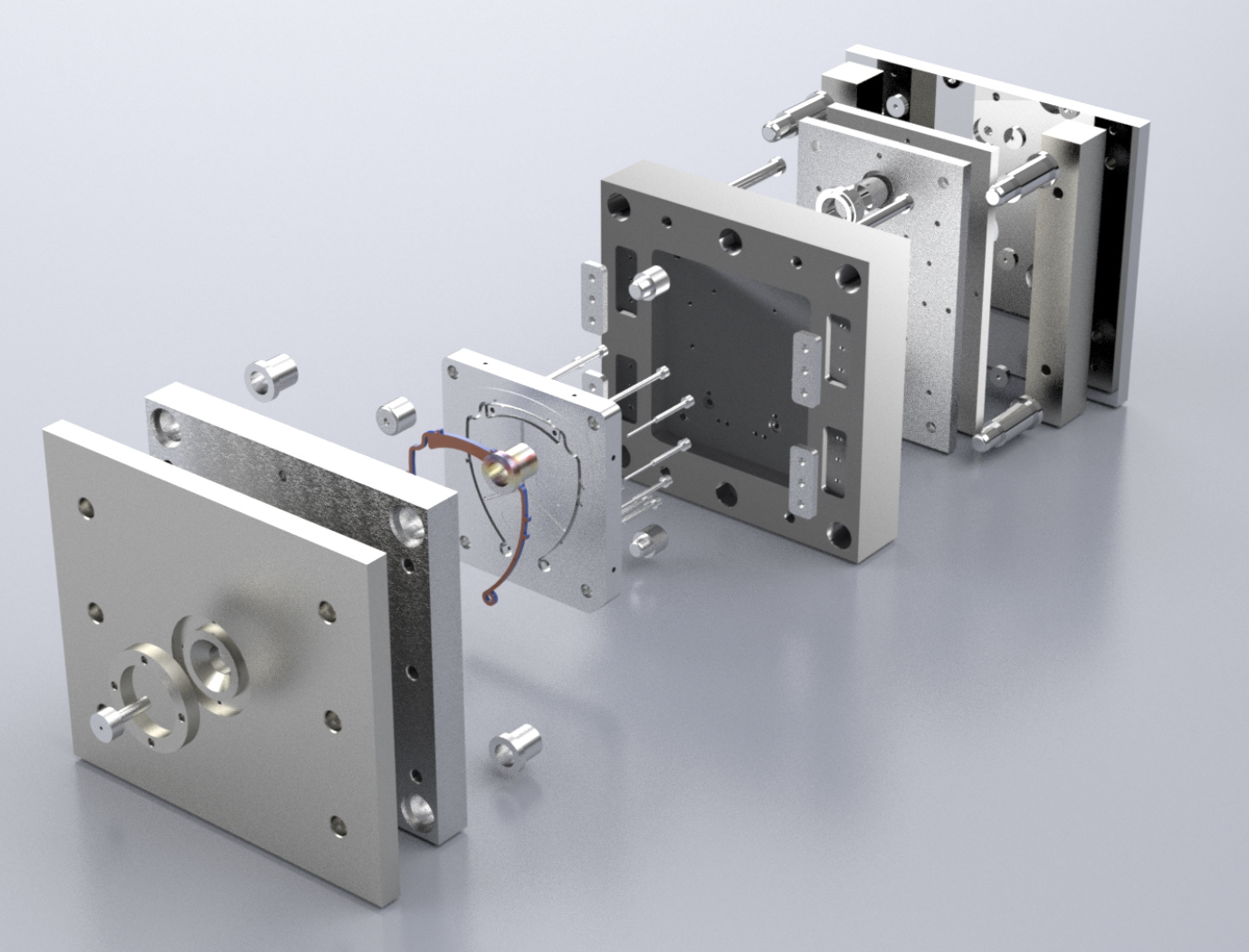

Components of Injection Molds

A plastic injection mold consists of a series of metal plates along with intricate machined components on both the cavity-side and core-side of the mold. All mold components are manufactured with very close tolerances and the overall quality of the mold will directly affect the part quality and the mold's useful life expectancy.

Cavity Side

The cavity side mounts to the stationary side of the machine platen and houses the following elements:

Locating ring

Locating ring Sprue bushing

Sprue bushing Guide pins

Guide pins Clamp plate

Clamp plate Cavity block

Cavity block

Core Side

The core side mounts to the moving platen and contains these components:

Core block

Core block Leader pin bushings

Leader pin bushings Support pillars

Support pillars Ejector pins

Ejector pins Return pins

Return pins Ejector retaining plate

Ejector retaining plate Ejector plate

Ejector plate Clamp plate

Clamp plate

Manufacturing Of Custom Plastic Molds

Building plastic injection molds involves two primary machining methods, EDM and CNC machining.

EDM Machining

This process involves using a copper or graphite electrode to electrically burn the specified mold shape into the mold component. EDM machining is slower and more costly than CNC machining, and it is only used for mold features that are not practical to cut with a CNC machine, such as sharp corners and very thin rib features. The steps of this method include:

CNC Machining

CNC machining uses advanced computer technology to cut complex and precise surface shapes into the mold materials. Our mold designers create a 3D model with the required mechanical dimensions and shapes of the mold details using CAD software. Final mold designs that are ready for machining can take one or two weeks to complete. The 3D CAD models within the final mold design are then used within our CAM software. Our CAM programmers can tell the software how to machine the raw metal into the final mold shape and the software creates the commands to execute in our CNC machines.

This plastic housing for aesthetic medical equipment is manufactured using high-precision injection molding technology, ensuring the accuracy and uniform wall thickness of the casing. The surface of the casing has undergone a special treatment that gives it a smooth touch and a high-gloss finish, enhancing the product's aesthetics and ease of cleaning and maintenance. The design takes into account ergonomic principles to ensure comfort and stability during use. Additionally, the casing is made from medical-grade plastic that meets FDA standards, ensuring safety when in contact with the skin. It is highly durable and can withstand frequent use and sterilization processes, making it an ideal choice for high-end aesthetic medical equipment.

Product Description

Smart Home Device Shell PA, POM, PEEK ±0.03mm to ±0.05mm Anti-Corrosion Coating The smart home device shell needs to be wear-resistant, impact-resistant, dustproof, and waterproof. Commonly used materials are ABS and PC/ABS blends, which offer excellent impact resistance and heat resistance. These materials are also suitable for polishing and painting, resulting in a smoother, stain-resistant exterior. Since these robots need to integrate precisely with various electronic and mechanical components, a high dimensional accuracy of around ±0.05mm is typically required. The shell design also needs to be ergonomic for user-friendly operation, which enhances its aesthetic appeal and market competitiveness.

Automotive Dashboard Shell

The automotive dashboard shell requires high heat resistance, durability, and aesthetic appeal. Materials like PC or ABS/PC blends are often used, as they offer a good surface texture and are easy to process, meeting the need for durability and resistance to long-term sun exposure without deformation. The dashboard panel demands precise dimensional control, generally around ±0.02mm, to ensure it fits well with various electronic and mechanical components, enhancing the ease of operation. The surface treatment usually involves a matte finish or painting to reduce glare and increase both touch comfort and a premium feel, improving user experience.

Ultrasound Device Shell in Medical Equipment

Ultrasound device shells require high chemical resistance, heat resistance, and compliance with strict hygiene standards. PC and PPSU are commonly chosen materials, offering high strength and ease of cleaning and disinfection, suitable for frequent use in medical settings. This type of shell requires extremely high precision (±0.01mm to ±0.02mm) to ensure sealing and secure connections with internal components. The shell typically retains its natural color or is treated with non-toxic coatings, and some are additionally treated with antibacterial coatings to meet safety and hygiene requirements in medical environments.

Product Title

1. Smart Home Device Shell

DurableABSShell for Smart Home Cleaners Dustproof Waterproof Customizable Size and Shape

High-Precision PC/ABS Shell for Home Cleaning Devices Impact-Resistant Scratch-Resistant

CustomRobotHousing for Smart Home Cleaners DustproofABS Material Polished Surface Waterproof Protective Shell for Floor and Pool Cleaning Devices UV-Resistant Lightweight Design

Anti-CollisionABS Plastic Shell forAutomated Cleaning Robots Custom Colors and Logos

2. Automotive Dashboard Shell

High-Quality PC Car Dashboard Shell Scratch-Resistant Durable Customizable Colors

Automotive Control Panel Shell High-PrecisionABS/PC Material Impact-Resistant UV-Protected

StylishAutomotive Console Shell Scratch-Resistant ABS Panel Custom Fit and Surface Finish

Customizable PC/ABS Central Console Shell for Car Interior Durable Precision Design Heat-Resistant Car Dashboard Shell Injection Molded Precision Support OEM Customization

3. Ultrasound Device Shell in Medical Equipment

Medical-Grade PC Shell for Ultrasound Devices Biocompatible High Precision

Durable PPSUShell for Medical Equipment Chemical Resistant Custom Size

Antibacterial PC Shell for Ultrasound Devices UV-Resistant Precision Design

Precision-Molded PC Shell for Ultrasound Devices Corrosion-Resistant Lightweight Design

High-Quality Medical Plastic Shell for Diagnostic Equipment Custom Fit Biocompatible