What We Do

Custom Plastic Injection Molding

Our rich experience as a premium plastic injection molding factory includes production capabilities for many different industries, plastic materials, and specialty add-ons for your custom plastic parts.

Our focus is on production runs of 100 to 100,000 units per order. We know every custom injection molding project is different, but every Mingyu Mold customer enjoys our key values:

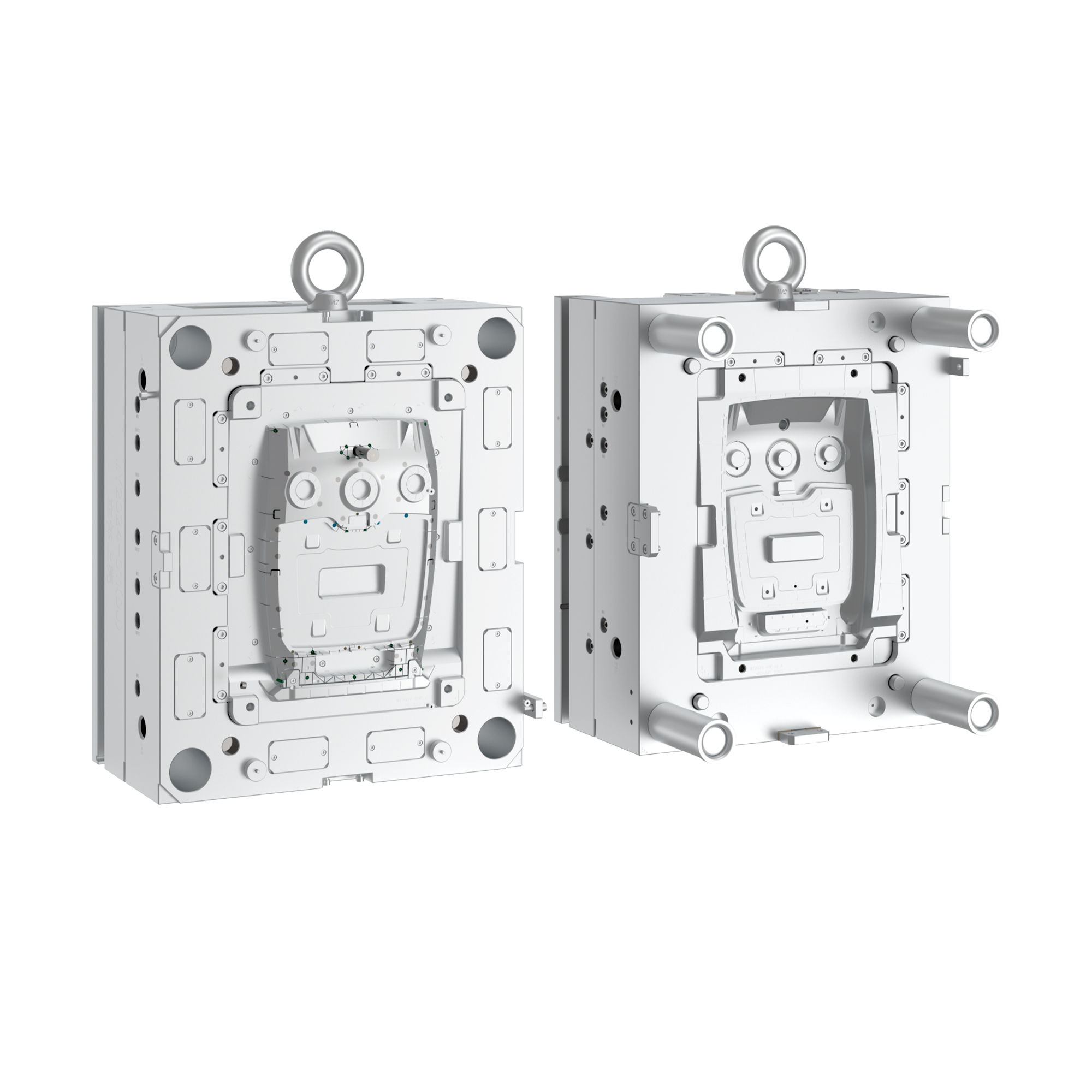

Injection Molding Projects Start With A Mold

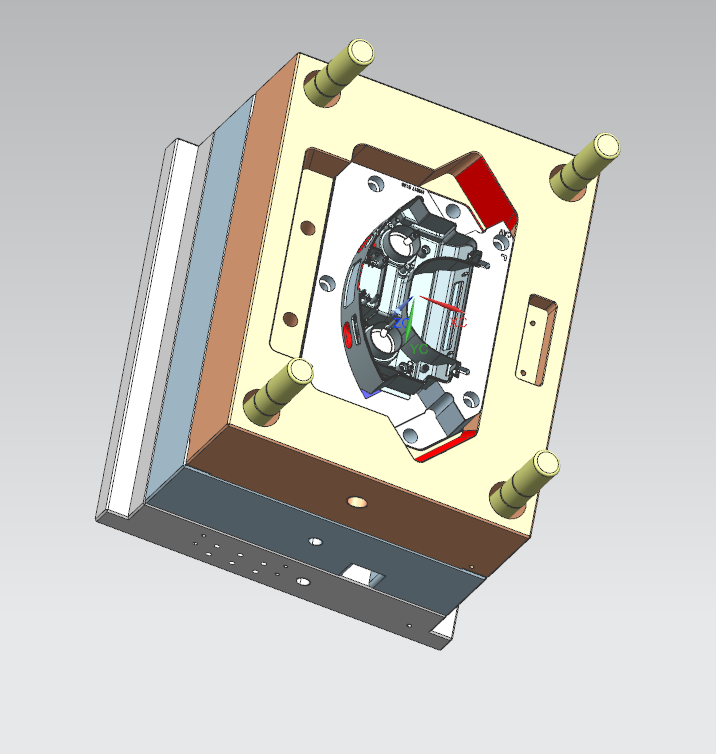

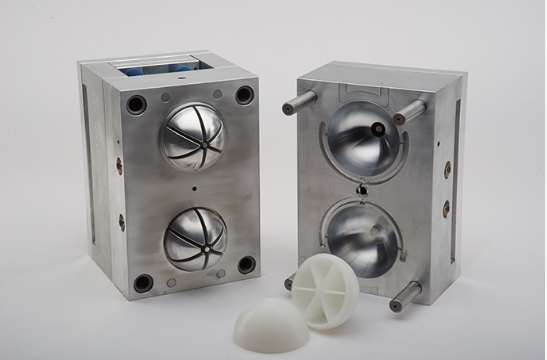

Receiving high-quality injection molded parts starts with a quality built mold. Molds for plastic injection require a significant investment so we’ll work with you every step of the way to ensure you’re familiar with the different types of molds that are available for your project. We’ll make sure you’re completely informed before you invest in your tooling. Below we provide you with a valuable understanding of basic injection mold construction types and the benefits of each.

What Is a Custom Plastic Mold?

Plastic Injection Molding Challenges

Two of the biggest challenges with plastic injection molding projects are the cost and lead time. At Mingyu Mold, we overcome these challenges by building all injection molds in-house. We have also developed rapid tooling systems that reduce costs and improve lead times without sacrificing quality. Interaction with our injection molding experts throughout the process ensures a seamless sourcing experience production of the best possible molded plastic parts.

Injection Molding Process

Plastic injection molding requires three primary components – an injection molding machine, a mold, and raw plastic material. Molds for plastic injection consist of high strength aluminum and steel components that have been machined to operate in two halves. The mold halves come together inside the molding machine to form your custom plastic part. The machine injects molten plastic into the mold, where it solidifies to become the final product. The injection molding process is actually a complex process with many variables of speed, time, temperatures and pressures. The complete process cycle for making each custom part can range from no more than a few seconds to several minutes. Below we offer you a very brief explanation of four steps of the molding process.

Selecting A Plastic Material For Your Parts

There is a wide variety of plastic material options for custom injection molding. It is most helpful for product engineers and designers to focus on the functional utility and working environment of their parts when selecting a plastic material. Talk to your injection molding supplier about these to help narrow down the right plastic material family for your custom injection molding project. At Mingyu Mold we are happy to provide consultation to help customers find the right plastic material choice for their custom molded parts.